Maximizing Durability and Performance: The Advanced Engineering of IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 Threaded Rods

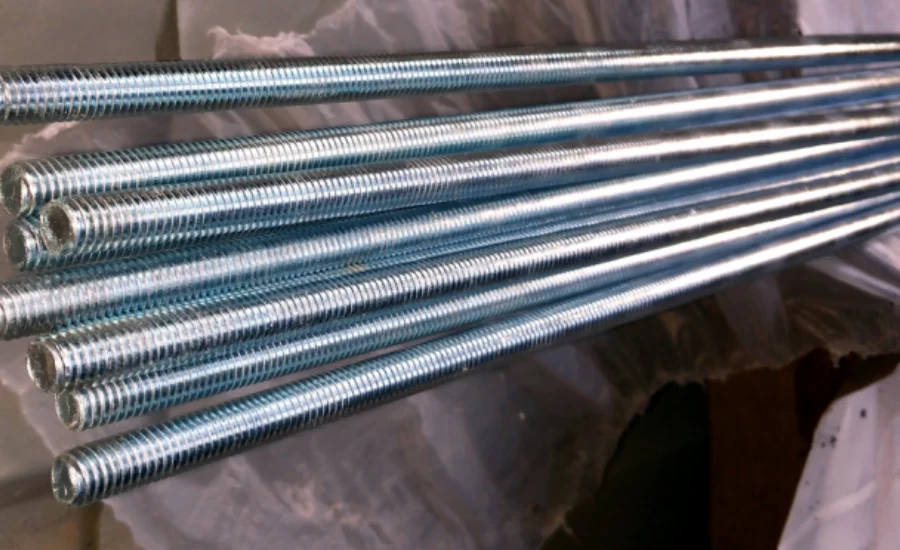

ige filetée zn 5.8 / hdg 5.8 m24 x 210; In the construction and heavy-duty sectors, selecting high-quality fasteners is crucial for the success and durability of any project. The IGE Filetée ZN 5.8 / HDG 5.8 M24 x 210 fastener distinguishes itself as a top choice due to its exceptional strength and reliability. This article provides a detailed overview of this advanced fastener, examining its key attributes, benefits, and best use cases.

The IGE Filetée ZN 5.8 / HDG 5.8 M24 x 210 fastener is made to withstand the demanding conditions found in heavy-duty and construction applications. It may be used in a variety of situations due to its exceptional corrosion resistance provided by its zinc-plated covering. Because of its strong substance, the fastener can withstand heavy loads and strains without losing its integrity.

Understanding the Significance of the “M24 x 210” Specification for Threaded Rods

Accurate measurements are essential for the correct functioning and security of threaded rods. A proper fit for the intended application is ensured by checking the dimensions, which also provides the required stability and support. It is crucial to pay close attention to detail during the production and installation procedures because any variations from these criteria may lead to incorrect installation or even structural issues. Maintaining the overall integrity and dependability of the building requires proper size.

Precise measurements in threaded rods are vital for their proper operation and safety. Ensuring the correct dimensions guarantees a perfect fit for the intended application, providing the necessary support and stability. Any deviations from these specifications can result in improper installation or potential structural problems, underscoring the importance of meticulous attention to detail during both manufacturing and installation processes. Correct sizing is essential to maintain the overall integrity and reliability of the structure.

In conclusion, the “M24 x 210” specification defines the key size parameters that affect the rod’s performance and suitability. Adhering to precise measurements ensures that the rod delivers the required support and stability for demanding applications. By following exact sizing guidelines, manufacturers and engineers can prevent potential issues and ensure that the threaded rod meets the rigorous standards needed for critical tasks.

High-Performance Features of the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 Threaded Rod

With remarkable strength and endurance, the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 threaded rod is designed for tough, heavy-duty applications. This sturdy steel rod has a 24 millimeter diameter and 210 millimeter length, making it capable of withstanding high loads and stresses. It is guaranteed to be able to bear significant forces without breaking thanks to its tensile strength rating of 5.8.

The rod’s resistance to corrosion is significantly enhanced by its zinc plating and Hot-Dip Galvanization (HDG) treatments. These coatings provide excellent protection against rust and degradation, extending the rod’s longevity and maintaining its structural integrity in various environmental conditions. This combination of high tensile strength and superior corrosion resistance makes the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 an ideal choice for critical and heavy-duty applications.

Benefits of Using the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 Threaded Rod

Choosing the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 threaded rod for your project offers a range of significant advantages, ensuring reliability and performance across various applications.

This threaded rod is renowned for its exceptional corrosion resistance, thanks to its zinc plating and Hot-Dip Galvanization (HDG). These protective coatings shield the rod from moisture, chemicals, and other corrosive elements, making it highly suitable for both outdoor settings and harsh industrial environments.

In terms of strength, the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 rod excels with a tensile strength rating of 5.8. This rating indicates its ability to support substantial loads and endure considerable stress, which is ideal for demanding tasks that require robust performance.

The versatility of this rod is another notable feature. It is designed to accommodate a wide array of applications, from large-scale construction projects to various DIY endeavors. This adaptability ensures dependable performance in diverse settings.

Installation is straightforward with this threaded rod, thanks to its metric thread design. This feature facilitates compatibility with standard nuts and washers, ensuring a secure and stable fit that simplifies the installation process.

Additionally, the durability of the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 rod offers excellent value for money. Its long-lasting strength reduces the need for frequent replacements, making it a cost-effective solution for numerous applications.

Versatile Applications and Advantages of the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 Threaded Rod

In the construction industry, the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 threaded rod is a key component for securing beams, columns, and other structural elements. Its high tensile strength and superior corrosion resistance make it an excellent choice for both temporary and permanent fastening tasks, ensuring stable and reliable connections in a range of structural applications.

For machinery and equipment, this threaded rod proves indispensable. Its robust construction allows it to withstand the rigors of heavy use and harsh environments, contributing to the safe and efficient operation of various mechanical systems. The IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210’s durability and strength make it a crucial element in machinery assembly and maintenance.

In the automotive sector, the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 threaded rod plays a vital role in assembling chassis and securing engine components. Its ability to handle substantial stress and maintain reliability under demanding conditions is essential for ensuring vehicle stability and safety on the road.

The rod’s notable tensile strength is a key factor in its performance. It is designed to bear significant loads and tension without deformation, making it a dependable choice where stability and safety are critical.

Corrosion resistance is another significant feature of this threaded rod. It benefits from a combination of zinc plating and hot-dip galvanizing. The zinc plating provides sacrificial protection, corroding before the underlying steel, while the hot-dip galvanizing offers a thick, durable coating that enhances the rod’s resistance to harsh environmental conditions and extends its lifespan.

In summary, the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 threaded rod excels in various demanding applications due to its strength, durability, and resistance to corrosion. Its versatility across construction, machinery, and automotive sectors underscores its value as a reliable and high-performance fastening solution.

Ensuring Optimal Performance: Best Practices for Installing the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 Threaded Rod

Proper installation of the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 threaded rod is crucial for ensuring its optimal performance and longevity. Adhering to the following guidelines will help you achieve a successful and reliable installation.

Begin by assembling all necessary tools, including wrenches, nuts, washers, and a torque wrench. Having these items readily available will streamline the installation process and reduce the likelihood of delays.

Correct alignment of the rod with the components it will fasten is essential. Proper alignment prevents uneven stress distribution, which could lead to potential failures. Ensuring that the rod is aligned accurately will help maintain the integrity of the connection.

Applying the proper amount of torque with a torque wrench is essential. To prevent both overtightening and undertightening, adhere to the torque setting recommended by the manufacturer. While undertightening could lead to a poor connection, overtightening could harm the rod and its components.

Use an anti-seize compound on the threads before to installation to improve performance and avoid problems like galling and sticking. This is particularly critical in high-stress applications where seamless functioning is essential.

Lastly, keep an eye out for corrosion on the rod by routinely inspecting it, especially if it is exposed to corrosive surroundings. In order to preserve the installation’s structural integrity and safety, any rusted rods must be replaced right away.

By following these installation practices, you ensure that the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 threaded rod performs at its best, delivering reliable and durable results in your applications.

Addressing Common Issues with the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 Threaded Rod

Even when working with a high-quality component like the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 threaded rod, various issues may arise during installation or use. Understanding these potential problems and their solutions can help ensure optimal performance and longevity.

One common issue is thread stripping, which can compromise the strength and reliability of the rod. To prevent thread stripping, it is important to use the correct tools and avoid over-tightening. If you notice stripped threads, replace the rod promptly to avoid failure and ensure the integrity of the installation.

Corrosion is another concern that can affect the rod’s durability. Regular inspections are crucial, particularly in harsh environments. Applying protective coatings can help mitigate corrosion, but if significant deterioration is observed, replacing the rod is necessary to maintain its performance and safety.

Misalignment during installation can lead to uneven stress distribution and early failure of the rod. Proper alignment is essential for optimal function, so ensure that the rod is correctly positioned and regularly check for alignment issues to prevent complications.

Nuts may become loose over time due to factors such as vibration or thermal expansion. To address this, consider using lock washers or thread-locking compounds to secure the nuts effectively. Regular inspections and re-tightening of nuts are also important for maintaining a stable and secure connection.

By proactively addressing these common issues, you can enhance the performance and reliability of the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 threaded rod, ensuring its effective use in your projects.

Comparing the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 Threaded Rod with Other Options

When selecting a threaded rod for your project, it’s essential to evaluate various options to ensure you choose the most suitable one. Here’s how the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 stands out in comparison to other commonly used threaded rods.

Standard zinc-plated rods provide a basic level of protection against corrosion but may not perform as well in extreme conditions. In contrast, the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 offers superior durability and corrosion resistance thanks to its hot-dip galvanization, making it an excellent choice for outdoor and industrial applications where enhanced protection is required.

For demanding applications, high-strength steel rods offer greater tensile strength, which is beneficial. If these rods are not properly handled, they can be more susceptible to corrosion. With its strong strength and efficient corrosion resistance, the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 is a flexible solution that can be used in a variety of settings without sacrificing longevity or performance.

High-strength steel rods deliver increased tensile strength, which is advantageous for demanding applications. However, these rods may be more vulnerable to corrosion if not adequately treated. The IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 combines robust strength with effective corrosion resistance, offering a versatile option that suits a range of applications while maintaining both performance and longevity.

In summary, the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 threaded rod provides a well-rounded solution with superior corrosion protection and strength, making it a valuable choice compared to standard zinc-plated rods, stainless steel rods, and high-strength steel rods.

Ensuring Optimal Performance and Longevity of Threaded Rods Through Proper Installation and Maintenance

It is crucial to install threaded rods correctly if you want to maximize their performance. The keys to getting the best outcomes during installation are using the right equipment and making sure everything is aligned precisely. Following the manufacturer’s directions is essential to prevent problems and ensure a secure fit. Improvements like pre-drilling holes and adding washers can greatly increase alignment and stability, which raises the assembly’s overall strength and dependability.

Threaded rods also benefit from regular maintenance to extend their lifespan and maintain performance. Routine inspections are important for detecting signs of corrosion, which can compromise the integrity of the rods. Additionally, it is vital to periodically check and tighten nuts and bolts to prevent loosening, which can impact performance. Reapplying protective coatings as necessary can further safeguard the rods from environmental factors, ensuring sustained protection and durability.

By following these best practices for both installation and maintenance, you can ensure that threaded rods deliver reliable performance throughout their service life. Proper care not only extends the lifespan of the rods but also enhances the safety and effectiveness of the structures or systems in which they are used.

Real-World Applications and Key Takeaways for the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 Threaded Rods

The IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 threaded rods have demonstrated their effectiveness in various high-profile projects. For example, during a major commercial construction project, these rods were instrumental in securing the metal framework, contributing significantly to the overall structural stability and integrity of the building.

These practical applications underscore the importance of selecting appropriate materials and adhering to best practices in installation and maintenance. The success of these threaded rods in diverse scenarios illustrates their versatility and reliability. By choosing the right components and following proper procedures, projects can achieve enhanced durability and performance.

Future Innovations and Sustainability in Threaded Rod Technology

Advancements in materials science and manufacturing techniques are poised to enhance the performance and durability of threaded rods significantly. Emerging technologies, such as smart materials and nanocoatings, are expected to revolutionize this sector. Nanocoatings, for instance, promise exceptional resistance to corrosion and wear, extending the lifespan of threaded rods. Meanwhile, smart materials could introduce adaptive properties, allowing threaded rods to respond to environmental changes, thereby improving their efficiency and longevity.

Simultaneously, the sector is placing an increasing amount of attention on sustainability. The greater use of recycled metals, which lowers the need for new raw materials and diminishes environmental effect, is one aspect of the transition towards ecologically friendly activities. To further promote a greener production cycle, energy-efficient manufacturing techniques and environmentally friendly coatings are becoming more common. In addition to promoting environmental preservation, these sustainable methods meet the growing need for long-lasting, environmentally friendly industrial solutions.

Final Words

For demanding applications in the equipment, automotive, and construction sectors, the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 threaded rod is a standout option. Because of its great tensile strength, remarkable resistance to corrosion, and adaptability, it is a crucial part of maintaining the stability and dependability of structures. Strong zinc plating and hot-dip galvanization improve the performance of the rod by increasing its resistance to environmental elements and lengthening its service life.

To maximize the performance and security of threaded rods, it is imperative to comprehend the significance of accurate measurements and appropriate installation techniques. Following these guidelines not only guarantees peak performance but also adds to the general stability and integrity of the projects in which they are applied.

Looking ahead, advancements in materials science and sustainability practices are set to further enhance the capabilities of threaded rods. Innovations such as smart materials and nanocoatings promise to improve performance and longevity, while increased use of recycled metals and eco-friendly manufacturing processes align with the growing demand for sustainable industrial solutions.

In summary, the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 threaded rod exemplifies excellence in engineering and material science, offering a reliable and high-performance solution for various industrial applications. By continuing to embrace advancements and sustainability, the industry can look forward to even more durable and environmentally friendly fastening solutions in the future.

For more information join us on BreainRusher.com